In its most general sense, procurement is the act of buying products or services from suppliers at competitive prices. These products and services can include anything such as raw materials, equipment, supplies, facilities, and labor. In large-scale business deals, the procurement process benefits from management programs. A procurement manager oversees the procurement process to keep it running more smoothly and efficiently.

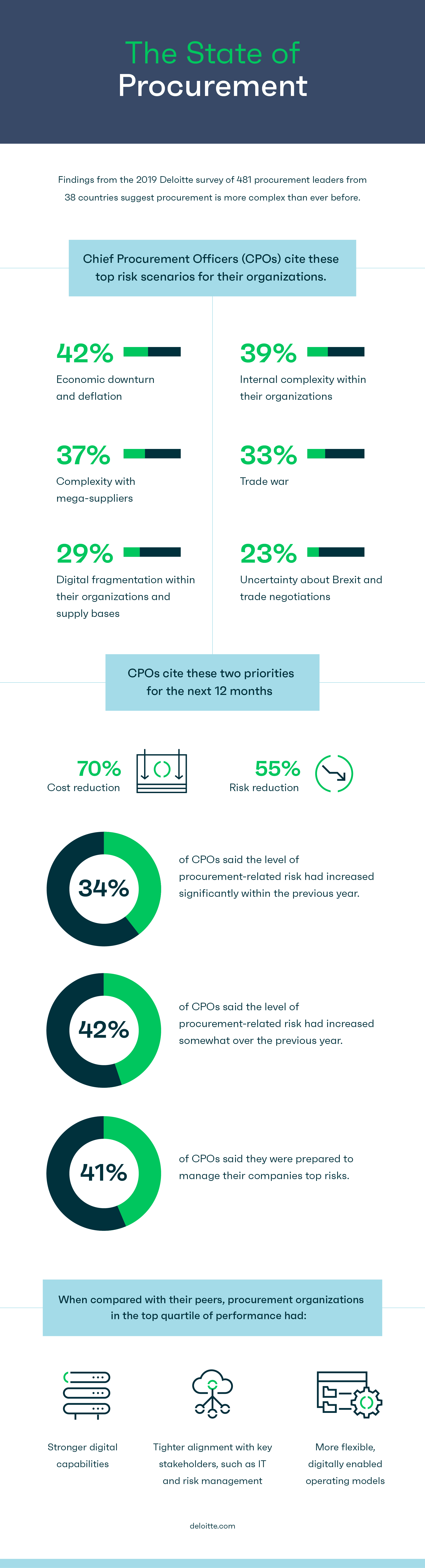

While that’s the simple definition of procurement management, procurement management itself is anything but simple. Managers must wear multiple hats and juggle numerous responsibilities to keep clients’ investment returns high while keeping overhead low. The procurement process has grown increasingly complicated and risky as customer demands and expectations grow. As we enter a new decade, we can expect procurement to become even more complex as competition increases and technology evolves. What are the emerging issues in procurement? Below we discuss some of the top issues.

Digitization and Technology

More than half (54 percent) of organizations have started to digitize and automate their standard procurement processes. Digitization reduces the need for cumbersome manual, pen-and-paper procurement, helps to remove tedious tasks, and leads to more efficient decision making. However, when companies switch to digital procurement, they face initial start-up costs and an inevitable learning curve. Further, not all suppliers are digitized, so if it’s not done thoughtfully, rolling out a digital procurement system can disrupt supplier relationships. But the trend towards digitization is clear.

Contract Compliance

Staying on top of supplier and vendor obligations can be daunting. As deals become more complicated and supplier lists grow, companies risk non-compliance. Non-compliance includes any deviation from the procurement process for any reason — from good intentions to intentional fraud. For example, contractors may avoid a fully competitive bid process to keep work for themselves or their allies. Manufacturers may substitute low-cost parts for agreed-upon parts. Or suppliers may miss deadlines or submit inflated cost data. Even a small lapse in a supplier’s delivery of its obligations can make the difference between a profitable and unprofitable procurement cycle.

Long Process Cycle

Clients’ demands for products and services tend to be urgent, which may create a long process cycle (the length of time from when someone requests a purchase to when a procurement manager authorizes an invoice for payment). A long process cycle means that a company’s lead times in obtaining goods and services extend much longer than the company desired or anticipated.

Why do urgent orders tend to create a long process cycle? When a company rushes to secure goods and services, the procurement department may make errors when preparing specifications or contracts. Or they may overlook the procurement schedule and shorten the bidding period or contract negotiation schedule. Ultimately, these or other factors may lead to increased risk, poor deliveries, and overpriced products.

Risk Mitigation

Procurement managers must continuously identify, assess, control, and monitor risk (any uncertain outcome that could impact the procurement process). They must monitor risks related to quality, cost, inventory, compliance, regulations, and fraud. Plus, each project presents additional specific risks.

While risk is inherent in any supply relationship, it’s dangerous to have too much risk or to fail to recognize risk. For instance, if a procurement manager fails to assess the financial health of a supplier, the supplier may go bankrupt or fail to meet its supply obligations, disrupting the entire supply chain. Multiply the unchecked risk inherent in each contract across a big project, and it may lead to a chaotic work environment. The procurement manager would then need to focus on putting out fires and crisis management instead of achieving a smooth, profitable procurement cycle.

Staying on top of risks from project start to end is a consuming, high-cost job, particularly as companies work with more vendors and regulations evolve.

Inaccurate Data

When a procurement department creates a purchase order with inaccurate or unreliable data, a company may end up losing money and time. Poor data management can cause excess inventory or inventory shortages, which can have a ripple effect down the line. Ultimately, inaccurate data may lead to profit loss.

Enhanced Market Intelligence

When companies source direct materials, procurement takes on increased strategic importance. To buy direct materials at the best price, a procurement manager needs to pay attention to changing economic factors and have a strong understanding of a company’s market. But it’s increasingly challenging for procurement managers to develop in-depth market intelligence because managers have more data sources to look at than ever before, including the internet, industry publications, price index forecasts, consultant reviews, and industry organizations. As data sources explode, managers must invest more time in market research and gathering data.

Contract Management

Procurement contract management involves the administration of contracts between a company and its vendors. Historically, the procurement contracting process was complex. Procurement departments managed hard-copy contracts or navigated desktop computers that housed the majority of contracts and data.

In the past few years, many companies have centralized and automated the procurement process with contract management software. Contract management software can increase flexibility and accessibility, lower costs, identify relevant data points, reduce delays, improve risk management, and facilitate audits.

Improved Stakeholder Alignment

Procurement stakeholders include internal end users such as budget owners, finance and legal departments, and senior management as well as external end users such as suppliers. Procurement managers must align their procurement strategies to the goals of all the internal and external stakeholders to inspire commitment and engagement.

But procurement managers face increasing challenges when aligning their strategies. Organizations innovate their supply chains quickly and constantly. At the same time, procurement departments often feel pressured to cut costs and produce a leaner bottom line. Procurement leaders need to propose and adopt new ideas and provide solutions to stakeholders’ challenges to showcase that they champion the same goals as the stakeholders.

The Way Forward

Procurement leaders can help alleviate the risks and costs of all of the emerging issues in the procurement process by investing in contract management systems. “No longer simply a buzzword, digital transformation is becoming an imperative for top-performing procurement organizations,” concluded Deloitte researchers in their 2019 Global Chief Procurement Survey.

The right software can help a company manage everything involved in procurement from evaluating and selecting vendors to creating and monitoring agreements. Procurement software boasts analytical abilities to help procurement departments increase compliance and reduce risk. It helps organizations keep relevant stakeholders on the same page without time-consuming meetings or calls. It reduces the amount of inaccurate data in documents. And it helps companies enhance their market intelligence and shorten the process cycle. By embracing contract management software, procurement leaders can improve their agility and decision making and boost their returns on investment while lowering their costs and pleasing shareholders.